Since the 1950s, nearly 9 billion metric tons of plastic have been produced. Because plastic was not designed to be biodegradable or recyclable when it was created, the majority of that waste is still in landfills and other unintended dump sites. Even with modern efforts, less than one-third of polyethylene terephthalate (PET) materials are recycled in the United States. While many companies around the world are working to create products made entirely of recycled materials that use less plastic, a circular plastics approach is not the most environmentally friendly. Each reuse includes reprocessing, which involves the addition of new materials to restore recycled materials to like-new condition. These materials must be discarded after two or three recycling processes because their quality is too degraded to recycle. Industry experts have begun to focus their efforts on more sustainable packaging manufacturing, which includes the use of fully biodegradable and renewable solutions.

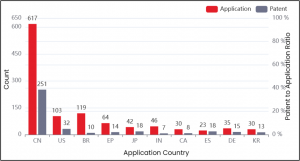

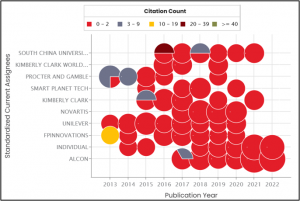

China has dominated the sustainable packaging sector. US appears to be ramping up innovation in this space, with numerous applications but few published patents.

Types of Environmentally Friendly Plastics

1. Polylactic Acid-Based Plastic (PLA)

Because it is 100% renewable, bio sourced, and biodegradable, it is considered the most appealing sustainable biopolymer currently available. PLA is made from lactic acid, which is produced by fermenting dextrose in sugar cane or corn. As a result, the thermoplastic polyester end product has a high melting point, mechanical strength, and transparency, making it very comparable to mainstream polymers. However, PLA has some drawbacks on its own. It is quite brittle and lacks sufficient impact strength, both of which limit its application. According to research, PLA’s flaws can be mitigated by combining it with natural polymers such as starch and cellulose, which are also used in the sustainable packaging industry.

2. Thermo-Plastically Modified Starch Blends (TPS)

Starch is one of the most widely available green materials on the planet, and it is playing an increasingly important role in the development of sustainable packaging sources. It is synthesized and stored by plants such as sugar cane, corn, potatoes, and other tubular vegetation to reinforce their structure and serve as an energy reserve. Starch disintegrates in water on its own and cannot be melt-processed like traditional plastics. TPS is created by combining native starch, water, and a plasticizer such as sorbitol, glycerol, or glucose to achieve thermoplastic properties. Compostable plastics, such as PLA, can also be used to address these drawbacks and strengthen PLA’s own weak points. TPS products, as a result, produce a more sustainable plastic that improves water resistance, lowers material costs, and enhances mechanical and processing properties.

3. Cellulose-Based Plastics

Cellulose is a completely organic compound found in the stem walls of all plants and in every plant cell, making it one of the most naturally occurring and sustainable polymers on the planet. Heat is used to extract cellulose fibers from materials such as wood pulp and cotton liners. Although cellulose is insoluble, its nanofibers are remarkably moisture sensitive. They can absorb moisture, lose their gas barrier properties, and mold or rot. This is yet another polymer that could benefit from the addition of PLA. Similarly, to TPS, the water resistance of cellulose plastic or acetate can be enhanced with PLA, resulting in a more robust and dependable product.

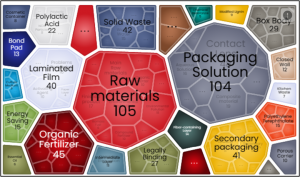

The Future of Sustainable Packaging

Food packaging, disposable eating utensils, compostable bags, and protective packaging can all be made with PLA, TPS, and cellulose-based plastics. Cost-wise, these sustainable plastic (sustainable packaging) options are not more cost-effective than traditional petroleum plastics. Having said that, the outlook for eco-friendly plastics is extremely promising. The global market for these and similar biodegradable alternatives was around $4.1 billion in 2021. Petroleum prices are rising in tandem with the demand for green materials. Consequently, the green materials market is expected to grow at a rate of nearly 10% per year through 2030.

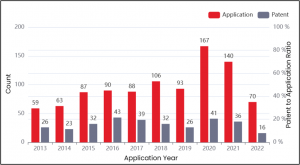

Organizations appear to be filing to incorporate sustainability into their existing product lines. This may also imply that businesses in the same or similar industries will license sustainable plastics technology. Using its powerful AI engine, XLSCOUT’s Techscaper reveals these insights, allowing inventors to quickly complete a thorough, up-to-date survey of the landscape for potential opportunities and to inform IP strategy.